Product Details

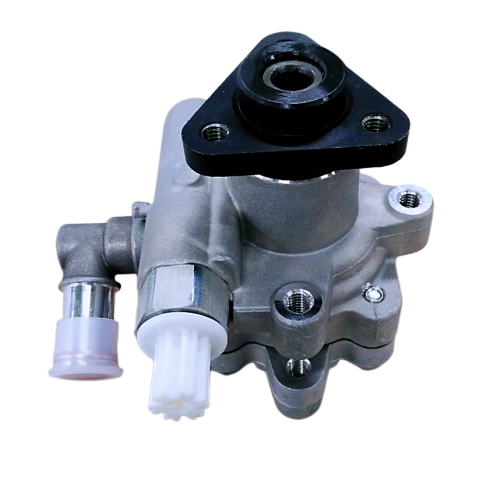

Hydraulic Oil Pump for Transmission

Subcategory

Keywords

- Description

-

Product Attributes

Model No.:FBB23

Brand:FZB

Place Of Origin:China

Type:External Gearing

Application:DCTPackaging & Delivery

Selling Units:Piece/Pieces

Package Type:PAPER BOX, PALLETProduct Description

Automatic Transmission Oil Pump

The automatic transmission oil pump, also known as the Gear Pump, plays a very important role in the automatic transmission and is one of the most important assemblies of the automatic transmission.

The oil pump is installed at the rear of the hydraulic torque converter and driven by the shaft sleeve at the rear of the hydraulic torque converter. In the oil supply system of automatic transmission, the commonly used oil pumps include internal gear oil pump, rotor oil pump, and vane oil pump.

The structure of the automatic transmission oil pump consists of an oil seal, an oil pump front end cover, an O-ring seal, a pinion, an internal gear, an oil pump rear end cover, and a seal ring.

DARE AUTO is a worldwide known transmission oil pump manufacturer in China, mainly supplying automotive and transmission OEMs globally. DARE AUTO is able to design the pump and software according to Customer’s technical specifications. With a robust global engineering team, DARE AUTO is able to provide customized solution.

Critical parametersPart Name Transmission Oil Pump Function Master Oil Pump DARE PN FBB23 Application DCT Type of Pump External Gearing Max. Pressure 52bar Speed Range 660-7000r/min Flow Rate 60L/min Working Temperature -40 to 130℃ Gerotor pump

As shown in Figure 3, a rotor pump consists of an inner and outer rotor, with the inner rotor having one tooth less than the outer rotor. There is no crescent shaped partition plate in the rotor pump. The shape of the convex surface of the rotor teeth keeps the teeth in tangential contact, and each inner tooth of the rotor pump continuously slides into contact with the outer tooth surface, which ensures the sealing of the working cavity between the inner and outer teeth (oil suction cavity and oil discharge cavity) and prevents the leakage of pressure oil.

The sliding speed between the inner and outer tooth contact surfaces of the rotor pump is relatively low, thereby reducing the wear of the contact surfaces. The shaft rotates 6-13 revolutions (depending on the number of teeth) and the contact point completes a cycle. The opening and closing of the interdental cavity is gradually accomplished through long oil suction and discharge ports, which minimizes oil pressure shocks and flow fluctuations.

Related Products

Product Consulting

* Note: Please be sure to fill in the information accurately and keep the communication unblocked. We will contact you as soon as possible