Product Details

Electric steering motor

Subcategory

Keywords

- Description

-

Product Attributes

Model: FM01

Brand: FZB

Origin: ChinaPackaging and Delivery

Sales Unit: Piece

Packaging Type: Paper Box, PalletDescription

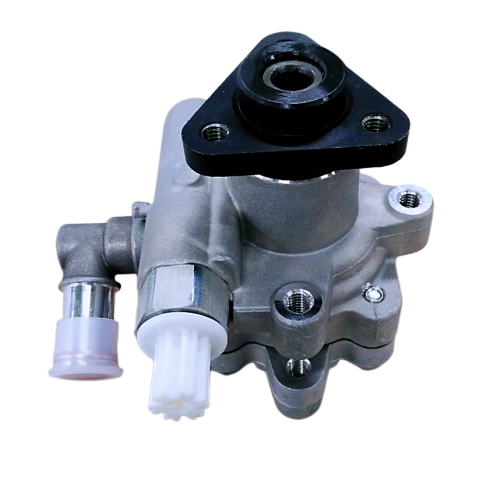

Electric Power Steering (EPS) Motor

The electric power steering motor uses the power generated by the motor to assist the driver in steering. The components of EPS generally include a torque (steering) sensor, electronic control unit, motor, reducer, mechanical steering device, and auxiliary battery power supply. Compared to mechanical hydraulic power steering systems, electric power steering systems only require power and do not need hydraulic components, thus eliminating many parts. There are no oil pumps, oil pipes, pressure and flow control valves, oil tanks, etc. The hydraulic system requires fewer parts, is easier to arrange, and is lighter. Additionally, there are no parasitic losses or fluid leakage losses. Therefore, the electric power steering system can save about 80% energy under various driving conditions, improving the vehicle's driving performance. It has rapidly gained popularity in recent years and is the development direction of future power steering systems.

Key ParametersParameters FM01 Series Rated Load Voltage-U 13.5 V Current-I Maximum 80A (Peak) Power/Torque 420 W/3.8N.m Speed 1050rpm Slot Torque Maximum 0.030Nm Friction Torque Maximum 0.027Nm Noise Maximum 45 dB When the brake pedal is pressed, a cone valve opens, allowing air to rush into the pressure chamber located on the driver's side of the booster. The pressure exerted by the air on the vacuum pushes the piston, thereby assisting the driver in applying pressure to the pedal.

1. When the engine starts, the hydraulic power steering begins to work, but EPS is not connected to the engine. Therefore, there is no fuel consumption.

2. The main components of EPS can be integrated together, making it easier to arrange compared to hydraulic power steering systems, reducing several components such as the Hps pump, hoses, valves, and reservoirs.

3. The efficiency of hydraulic power steering systems is generally 60% to 70%, while EPS can achieve an efficiency of over 90%.

4. By adjusting the software of the EPS controller, optimal returnability can be achieved, thereby improving driving stability and comfort.

Related Products

Product Consulting

* Note: Please be sure to fill in the information accurately and keep the communication unblocked. We will contact you as soon as possible