Product Details

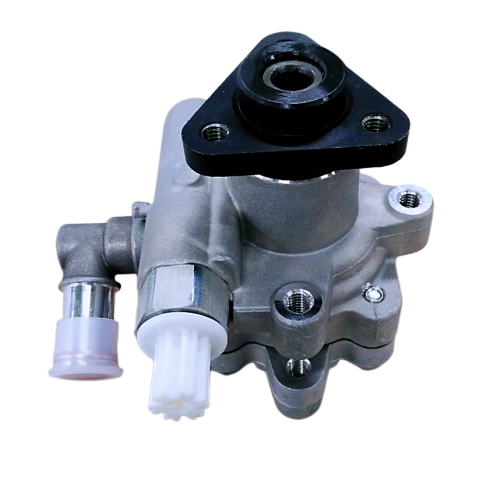

Modern Hydraulic Power Steering Pump

Subcategory

Keywords

- Description

-

Product Attributes

Product Model: FZB30B19

Product Brand: FZB

Product Origin: ChinaPackaging and Delivery

Sales Unit: Piece

Packaging Type: Paper Box, PalletDescription

How to replace power steering fluid?

The oil change method is as follows:

1. Support the front axle, keeping the wheels off the ground.

2. Remove the oil reservoir cap, disconnect the return line and drain plug.

3. Start the engine and run at high speed for about 10 minutes to drain the hydraulic oil from the reservoir, power steering pump, and inside the steering gear.

4. Turn off the engine, turn the steering wheel left and right to the limit, and drain the remaining hydraulic oil.

5. Replace the filter element, add hydraulic oil to the specified height, and bleed the air from the hydraulic system.

Key ParametersProduct Name Hydraulic Power Steering Pump Product Function Provide hydraulic oil to the steering gear Pump Model Vane Pump Product Number FZB30B19 REF. PN 5990955189 OEM PN 93340671, 947111866 Product Application GM-CELTA/Corsa/Prisma Displacement 6.88 ml/r Maximum Pressure 7.5-8.5 Mpa Speed Range 550-7000 r/min Flow Rate 6.0±1 L/min Air Inlet φ16 mm Air Outlet M16×1.5 Rotation Direction Right Maintenance of Power Steering Pump

1. The steering pump should be securely mounted on the pump bracket, ensuring that the pump pulley is in the same plane as the engine crankshaft pulley and tensioner pulley. The belt should be tensioned using a tensioner pulley or other tensioning methods. Tension: New belt: 45~55kgf, Old belt: 35~45kgf.

2. When the vehicle is turning, minimize the time spent in the kill zone (no more than 10 seconds when the engine speed is below 1500 RPM, and no more than 4 seconds when the engine speed is above 1500 RPM), otherwise, the steering pump will generate excessive heat, reducing its lifespan.

3. The steering system should be filled with steering fluid according to standard requirements, with the designated steering fluid being Dexron III.

4. The operating temperature for the steering system is -40℃ to 35℃.

5. When adding steering fluid, the fluid level should meet the requirements (within the "cold level" range specified by the dipstick, and when the oil temperature rises to 80℃, the level should be within the "hot level" range).

6. Various clearances of the internal parts of the steering pump are optional, so disassembly, replacement, or repair of the steering pump itself is generally not allowed.

7. Method for replacing steering fluid and bleeding:

7.1 Lift the front of the vehicle;

7.2 Disconnect the inlet and return lines of the oil tank, draining the hydraulic oil into a container;

7.3 Disconnect the return line joint of the steering gear, draining the hydraulic oil into the container;

7.4 Turn the steering to both limit positions several times to drain the oil from the cylinders on both sides of the steering gear (at this time, the oil will drain from the steering gear return port);

7.5 Disconnect all oil lines and drain the residual oil from the lines;

7.6 Reinstall all oil lines to their original state;

7.7 Pour the filtered steering fluid into the oil tank;

7.8 Start the engine. At this time, the oil level will drop. Quickly stop the engine, refill the liquid to the "cold level" position, and then start the engine. Turn left and right to the limit, with a dead time of 2-3 seconds.

7.9 Turn off the engine and recheck the oil level in the tank, which should be within the "cold level" range; otherwise, liquid should be added.

7.10 Bleeding method: Start the engine at a speed of around 1000 RPM or less, turning the steering wheel to the limit position several times, each time lasting 2-3 seconds. Then turn the steering wheel to the middle position and let the engine idle for 3-5 minutes. Observe whether the bubbles in the tank disappear. If the bubbles do not disappear, repeat the above steps and check again. If the problem persists, check for leaks in the system (see troubleshooting section).

8. The height of the steering fluid level will change when the steering system is working or not working (the fluid level can increase by a maximum of 5mm);

9. Generally, there will be no faults inside the steering pump. Do not disassemble or replace parts at will. If the cleanliness of the steering system is poor, the control valve nut of the booster pump can be removed, the valve chamber can be cleaned, and then dried with clean compressed air.

Related Products

Product Consulting

* Note: Please be sure to fill in the information accurately and keep the communication unblocked. We will contact you as soon as possible