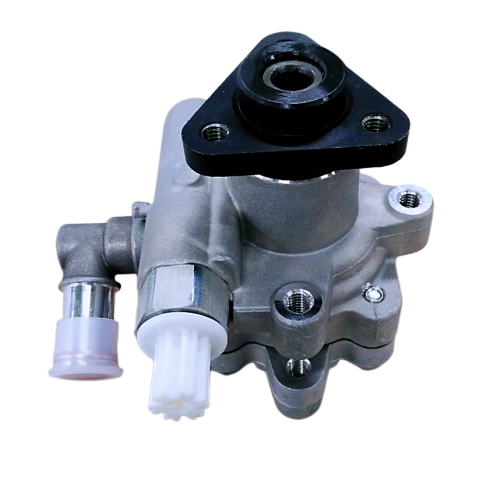

Product Details

Efficient Power Steering Pump

Subcategory

Keywords

- Description

-

Product Attributes

Model: FZB30B18A

Brand: FZB

Origin: ChinaPackaging and Delivery

Sales Unit: Piece

Packaging Type: Paper Box, PalletDescription

The steering pump makes abnormal noises.

Inspection and Analysis: The installation of the pump's upper bracket is loose; the power steering system's oil level is too low or there is insufficient air; the filter element in the oil cup is very dirty, leading to insufficient oil absorption by the steering pump. The internal cleanliness of the power steering system is poor, causing excessive wear of the stator, rotor, oil distributor, end cover, and oil pump input shaft.

Handling Method: Tighten loose parts, add steering fluid at designated locations, bleed air, and clean the steering pump.

Key ParametersProduct Name Hydraulic Power Steering Pump Product Function Provide hydraulic oil for the steering gear. Pump Model Vane Pump Product Number FZB30B18A REF. PN 5990955188 OEM PN 93322503 Product Application GM CORSA Displacement 9.3 ml/r Maximum Pressure 6.0-7.0 Mpa Speed Range 500-7000 r/min Flow Rate 6±1 L/min Inlet φ15.9 mm Outlet M16×1.5 Rotation Direction Right Fault Causes and Exclusions

The power pump for the steering gear does not absorb oil or the oil output pressure is too low.

Fault Causes:

1. Filter element blockage, oil pipe blockage due to rubber corrosion resistance.

2. Air leakage at the oil pipe joint, allowing air to enter.

3. Wear of the booster pump parts, excessive clearance, leading to weak oil output.

4. Oil does not meet requirements or has been used for too long, with excessive viscosity and high sliding resistance of the blades.

5. The oil level in the storage tank is too low.

Remedial Plan:

1. Clean the filter element with alcohol, replace the oil pipe, and add hydraulic oil to the specified level.

2. Check the tightly connected parts to prevent air from entering.

3. Check and repair the booster pump, replacing severely worn parts.

Related Products

Product Consulting

* Note: Please be sure to fill in the information accurately and keep the communication unblocked. We will contact you as soon as possible