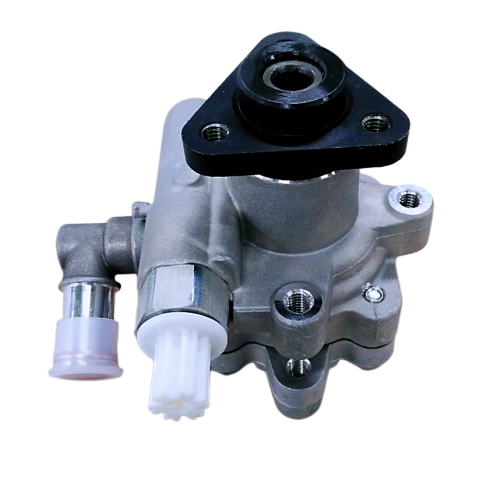

Product Details

Power Steering Pump with Good Efficiency

Subcategory

Keywords

- Description

-

Product Attributes

Model No.:FZB13F2C

Brand:FZB

Place Of Origin:ChinaPackaging & Delivery

Selling Units:Piece/Pieces

Package Type:PAPER BOX, PALLETProduct Description

Selection of steering pipe inlet and outlet pipes

Selection of pipeline material: The pipeline can be flexible pipe, steel pipe, or mixed type. The hose is further divided into high-pressure steel wire braided oil resistant hose, high-pressure oil resistant plastic hose, and low-pressure cord braided oil resistant hose; The steel pipe is high-pressure seamless steel pipe, and the material is generally 20 steel or 08F steel.

The selection of oil pipes, whether steel pipes, oil resistant rubber pipes, or plastic pipes, must be based on the working pressure of the system. It is recommended not to use high-pressure steel wire to weave oil resistant hoses to avoid reducing the inner diameter of the pipeline due to temperature rise and expansion. It is best to use high-pressure steel pipes.

Selection of pipe inner diameter:

Selection of pipe inner diameter: Determine the pipe inner diameter size based on the flow rate in the pipe. The recommended allowable flow rate is:

1) Hydraulic pump oil suction pipeline: 0.5~1.5 m/s. Generally, it is taken as below 1 m/s.

2) Hydraulic system pressure oil pipeline: 3~m/s. The maximum value is taken when the pressure is high.

3) Hydraulic system oil return pipeline: 1.5~2.5 m/s.

Critical parametersPart Name Hydraulic Power Steering Pump Function Provide hydraulic fluid to steering gear Type Vane pump DARE PN FZB13F2C REF. PN OEM PN EN1-3A674-AA Application JMC Nom. Displacement 9.6 ml/r Max. Pressure 10±0.35 Mpa Speed Range 500~7500 rpm Flow Rate 7.2-8.8 L/min Inlet Port Ф14 mm Outlet Port M16X1.5 Direction of Rotation Right Power Steering Oil & Filter Change Procedure

Clean off thoroughly steering gear body and bottom poppet adjuster screw and the nearby surfaces.

Measure the poppet adjuster screw height from the housing surface. Loosen the seal nut remove nut and screw. Drain oil by turning the steering lock to lock few times.

Inspect the poppet adjuster screw threads and clean. Install the adjuster screw in the same position as before. Screw the seal nut (Replace the seal nut if the original one is damaged in the seal area) and tighten it to certain torque.

Wipe dry reservoir inner surface with clean cloth (without loose threads) and install new cartridge and cover seal.

Connect the suction hose and tighten the hose cap nut.

Related Products

Product Consulting

* Note: Please be sure to fill in the information accurately and keep the communication unblocked. We will contact you as soon as possible