Product Details

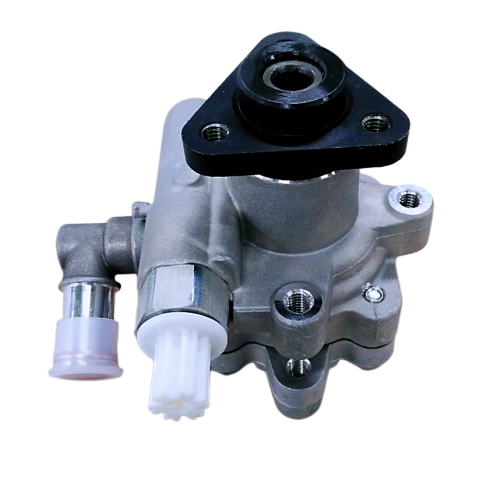

Electric Hydrulic Power Steering Pump 3KW

Subcategory

Keywords

- Description

-

Product Attributes

Model No.:FDB639A

Brand:FZB

Place Of Origin:ChinaPackaging & Delivery

Selling Units:Piece/Pieces

Package Type:PAPER BOX, PALLETProduct Description

DARE AUTO is a professional manufacturer of high voltage Electric Hydraulic Power Steering Pump in China, and dedicated itself in supplying automotive OEMs and Tier 1 OEMs globally. DARE AUTO is able to design the Electric Steering Pump and software according to Customer’s technical specifications. With a robust global engineering team, DARE AUTO is able to provide customized solution.

Critical parametersFunction Power steering Vehicle application 10-12m electric bus, heavy truck Pump model Vane pump Motor model Permanent magnet synchronous motor Max. output flow 14-20L/min Max. working pressure 14-18MPa Motor working voltage 200-380V AC Motor peak power 3.0KW Working ambient temp. -40℃~+80℃ Electric input parameters Enable, speed (optional) Protection grade IP67 Communication mode CAN Fully conforms to “Quick response” requirement

- Steering velocity is calculated according to the steering angle received.

- A proprietary algorithm is uesd for quick response to steering maneuvers.

- Steering velocity acceleration rate is also taken into account and utilized to improve the quick response performance.

Less current consumption compared to other equivalent products

- Control algorithm is designed to minimize the chance of generating huge current spikes.

- Motor control phase advance angle is monitored and controlled using current consumption feedback.

- Motor control angle is optimized to reduce current consumption at idle speed.

Better NVH performance

- Motor design: better PMSM electric motor helps to produce required torque while keeping itself quieter.

- Gear Pump design: customized gear pump design helps to improve the NVH performance.

- Electrical hardware: motor position sensing technology helps to reduce torque ripples.

- Control software: precise control algorithms (including sinusoidal motor control) help to reduce the fluid turbulence in the fluid.

Related Products

Product Consulting

* Note: Please be sure to fill in the information accurately and keep the communication unblocked. We will contact you as soon as possible