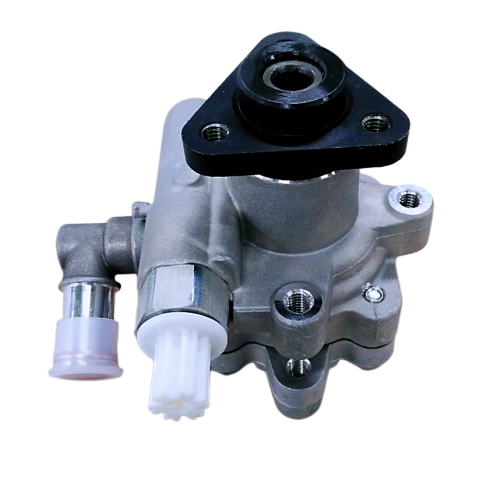

Product Details

Electric water pump for engine cooling

Subcategory

Keywords

- Description

-

Product Attributes

Model No.:EWP - 120w

Brand:FZB

Place Of Origin:ChinaPackaging and Delivery

Sales Unit:Piece/Pieces

Package Type:PAPER BOX, PALLETProduct Description

Working principle of Electronic Water Pump

The ECU (electronic control unit) adjusts the duty ratio through PWM (pulse width modulation) based on feedback signals such as water temperature, and transmits the signal to the controller inside the electronic water pump. The controller controls the rotation of the motor based on the duty ratio, thereby driving the impeller rotor to rotate, thereby achieving coolant circulation.

Traditional mechanical water pumps operate based on engine speed, which results in the need for large power to drive even during cold starts with low flow requirements and under low load and high speed conditions. At this time, the cooling capacity provided is far greater than the actual cooling energy required by the engine, and requires large power to drive.

In this way, a large part of the cooling capacity of the mechanical water pump is wasted, which requires a lot of additional driving capacity, and the cooling effect is somewhat different from the actual needs of the engine, resulting in a decline in the power and economy of the engine. The electronic water pump can accurately control the flow rate by cooling the device's demand for coolant.

Critical parametersPart Name Electric Water Pump Function Cooling DARE PN EWP - 120w Application Battery and electric motor Flow Rate 35L/min max. Pressure 145kPa Voltage 12v & 24v Temperature 40~125℃ Weight <760g Structure of pump Closed Centrifugal Pump Type of motor BLDC Control mode PWM & LIN Automotive electronic water pumps, many new energy vehicles, motor homes, and other special vehicles are commonly used as micro water pumps for water circulation, cooling, or on-board water supply systems. This micro self priming pump is collectively referred to as automotive water pumps. The circular motion of the motor causes the diaphragm inside the pump to reciprocate through a mechanical device, thereby compressing and stretching the air in the pump chamber (fixed volume), and under the action of a one-way valve, forming a positive pressure at the outlet (the actual output pressure is related to the assistance received by the pump outlet and the characteristics of the pump); A vacuum is formed at the water inlet, creating a pressure difference with the outside atmospheric pressure. Under the effect of pressure difference, the water pressure is injected into the water inlet and then discharged from the water outlet. Under the action of kinetic energy transmitted by the motor, water is continuously sucked in and discharged, forming a relatively stable flow rate.

Related Products

Product Consulting

* Note: Please be sure to fill in the information accurately and keep the communication unblocked. We will contact you as soon as possible