Product Details

Twin Electric Oil Pump for DHT Transmission 13.5V

Subcategory

Keywords

- Description

-

Product Attributes

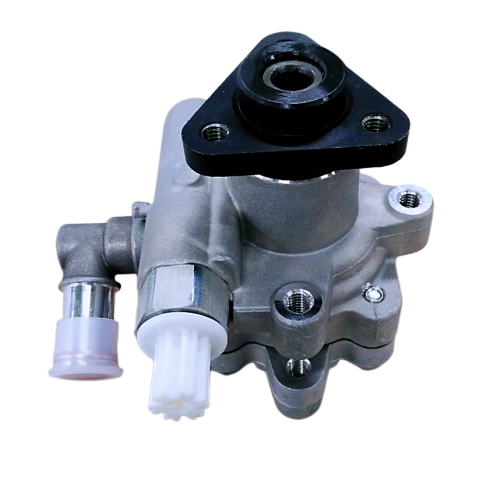

Model No.:FDB214F1C

Brand:FZB

Place Of Origin:China

Function:Pump 1: Gear shift, Energy storage; Pump 2: Cooling, Lubrication

Application:DHTPackaging & Delivery

Selling Units:Piece/Pieces

Package Type:PAPER BOX, PALLETProduct Description

The double electric oil pump FDB214F1C is composed with 2 pumps, driven by 1 motor, can operate according to instructions from controller and supply oil as required, realizing an obvious reduction in energy consumption.

This double electric oil pump is designed for Dedicated Hybrid Transmission, with the function of gear shifting and energy storage for pump 1, cooling and lubrication for pump 2. Working voltage is 13.5V, maximium working pressure is 55bar for pump 1 and 3bar for pump 2, flow rate is 21.2L/min, working temperature is between -40 ~ 85℃, CAN, PWM, LIN is optional for communication.

DARE AUTO is a customized solution provider and manufacturer of automatic transmission electric oil pump positioning in Fuxin, China, and DAER is dedicated to develop and produce pumps by supporting automotive industry moving forward. DARE has the capability to design all the components of electric oil pump and produce critical parts in-house. DARE can carry out all necessary simulations to exclude the potential risks and validate the performance and reliability by its own laboratory to ensure the robustness of the design. The electric oil pump is a highly integrated product including oil pump, motor, controller.

Critical parametersPart Name Transmission Electric Oil Pump Function Pump 1: Gear shift, Energy storage;Pump 2: Cooling, Lubrication DARE PN FDB214F1C Application DHT Working Voltage 13.5V Max. Pressure Pump 1: 55 bar, Pump 2: 3 bar Flow Rate 21.2L/min Working Temperature -40~85℃ Communication CAN, PWM, LIN About DHT transmission

The DHT transmission (Differential Heating and Transfer) is a special type of transmission that uses thermal differences and transmission methods to adjust the output speed. It implements a simple and effective transmission structure with the advantages of high accuracy and durability.

The DHT gearbox consists of two main components: a transmission wheel and a fan. The transmission wheel is composed of multiple turbines, and the outer surface of the turbine has spiral grooves. When external air enters, the grooves on the turbine generate a certain resistance, which can lead to changes in the rotational speed of the transmission wheel.

A fan is a fan device that sends outside air into the interior of the gearbox. When the fan rotates, it produces a certain resistance, which can lead to changes in the fan speed. Thermal differences are used between the two. When the external air temperature changes, the rotational speeds of the drive wheel and fan also change, thereby adjusting the output rotational speed.

Related Products

Product Consulting

* Note: Please be sure to fill in the information accurately and keep the communication unblocked. We will contact you as soon as possible