Product Details

Hydraulic Retarder - Braking System

Subcategory

Keywords

- Description

-

Product Attributes

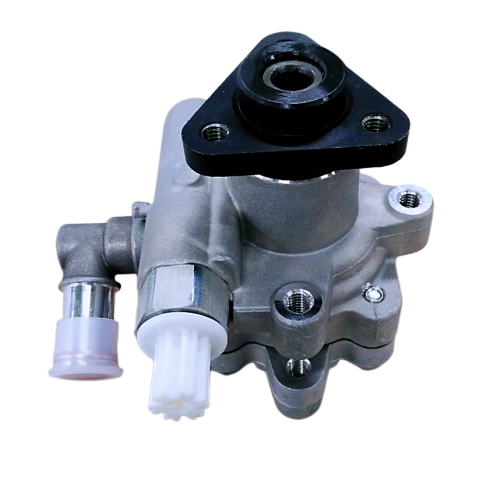

Model No.:FHQ325

Brand:FZB

Place Of Origin:ChinaPackaging & Delivery

Selling Units:Piece/Pieces

Package Type:PAPER BOX, PALLETProduct Description

Hydraulic Retarder

The automobile retarder energizes the excitation coil of the stator assembly through a control circuit to generate a magnetic field. The rotor assembly rotates at high speed with the vehicle transmission part, cutting magnetic lines of force, generating reverse torque, and slowing the vehicle.

According to their different working principles, automotive retarders can be divided into typical structural forms such as engine retarders, hydraulic retarders, electric turbine retarders, motor retarders, and aerodynamic retarders.

According to the different forms of braking torque action, automotive retarders can be divided into primary retarders (retarders acting on the front end of the gearbox) and secondary retarders (retarders acting on the rear end of the gearbox).

Critical parametersPart Name Hydraulic Retarder Function Auxiliary braking DARE PN FHQ325 Application CV braking assistance Max. Input Speed (rpm) 5300 Max. Braking Torque (N•m) 3250 Oil Filling Level (L) 6.8 Weight w/o Oil & Gear (kgs) 50.5 Connection Mode Parallel Working principle of the hydraulic retarder

1. Working principle:

The hydraulic retarder uses liquid damping to produce a retarding effect. The stator of the hydraulic retarder is also a retarder housing, which is connected to the rear end or frame of the transmission. The rotor is connected to the transmission shaft through a hollow shaft, and blades are cast on both the rotor and stator. During operation, pressure is applied to the oil pool through the operation of the control valve to fill the working cavity between the rotor and stator with working fluid. When the rotor rotates, a torque is applied to the stator through the working fluid. The reverse torque of the stator becomes the braking torque of the rotor, and its value depends on the amount of fluid and pressure in the working chamber (depending on the brake strength gear set by the control valve), as well as the rotational speed of the rotor.

2. Actual function:

The kinetic energy of the vehicle is consumed by the friction of the working fluid and the impact on the stator, which is converted into heat energy, causing the temperature of the working fluid to rise. The working fluid is introduced into the heat exchanger for circulation, transferring heat to cooling water, and then dispersed through the engine cooling system. In vehicles with hydraulic transmission, oil pools, oil pumps, heat exchangers (which need to be enlarged), and working fluids that utilize hydraulic transmission can be eliminated. Therefore, hydraulic retarders are mostly used in hydraulic transmission vehicles.

Related Products

Product Consulting

* Note: Please be sure to fill in the information accurately and keep the communication unblocked. We will contact you as soon as possible